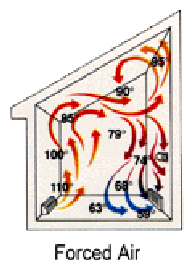

Radiant heating is a comfortable, healthy, and natural way to heat. Radiant heat warms the people and objects in the heated space rather than heating the air itself as forced air heating systems do. This is one of the main reasons radiant floor heating is 25% to 40% more efficient than forced air heating systems.

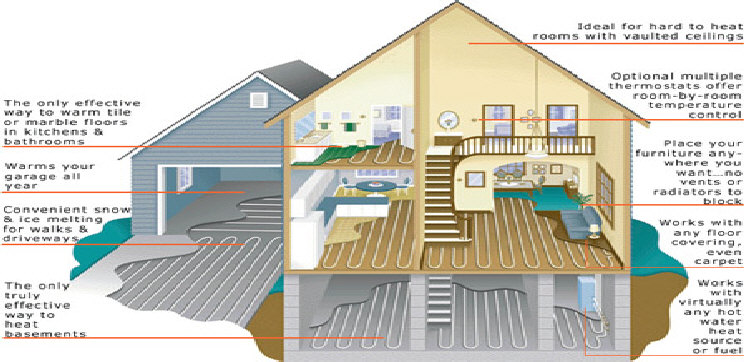

Because you are not heating the air directly, the escape of heat through the roof of the structure is greatly reduced. Drafts, colds spots, and dry air are also eliminated with radiant floor heating making it the perfect choice for today’s structures with vaulted ceilings. The diagrams to the right show the differences in temperature in relation to the space between forced air and radiant floor heating.

Radiant floor heating is perfect for people suffering from allergies. In a structure heated with radiant floor heating instead of forced air, dust settles out of the air on flat surfaces and can be cleaned and disposed of rather than blowing around in the air continually as in forced air heating systems.

Rooms are warmed with radiant heating by circulating heated water through flexible tubing installed in the floors, walls, or ceilings. The tubing distributes the heated water from a centrally located manifold location that receives heated water from a boiler. These tubes in the floor can be installed in a number of different ways depending on the construction of the building.

This picture shows the most common installation method when installing radiant tubing in a concrete slab, such as in a basement, or slab on grade for a home.

This picture shows the most common installation method when installing radiant tubing

on frame built first or second story sub-

This picture shows tubing installed using a plywood track system commonly used in

a retro-

This picture shows tubing installed below the sub-